Model : Customized Sizes

Feed Size: < 25 mm

Capacity: 0.1-230 (t/h)

Application: Cement, mineral, coal, limestone, gypsum, slag, etc.

1. Large capacity and continuous work are obvious advantages;

2. Various barrel lining and grinding media, excellent corrosion resistance;

3. Large capacity and crushing ratio; High grinding efficiency, low energy consumption;

4. Large application range, simple structure and convenient maintenance;

5. Good sealing performance. It can be adapted to different working conditions;

6. Product fineness is adjustable, uniform and highly qualified.

7. Installation and adjustment are very convenient and easy to operate.

Energy-saving ball mill is a new type grinding equipment transformed from the traditional ball mill, it is possible to reduce energy consumption, and increase the grinding capacity. It is mainly used for cement, powder plant, refractories, chemical, aluminum, building material, ceramic, steel slag and other production industry. It follows more crushing and less grinding principle to save energy and the outlet material sizes can be adjusted by revising steel balls ratio.

We supply ball mills for the following materials:

Cement, limestone, clinker, coal, marble, granite, slag, quartz, feldspar, calcite, barite, zircon sand, fly ash, magnetite, molybdenite, hematite, fluorspar, lead & zinc, manganese, tungsten, etc.

We have rich project experience in many countries, such as Indonesia, Malaysia, Vietnam, Iran, Kuwait, Turkey, India, Pakistan, Venezuela, Bolivia, Guyana, Russia, Armenia, Tanzania, and many more. Looking forward to your inquiry, we will give you professional suggestion, perfect service and best price.

.jpg)

| Both Standard & Customized Sizes Available | |||||||

|

Model |

Drum Size (m) |

Speed (r/min) |

Ball Weigh(t) |

Feed Size (mm) |

Output Size (mm) |

Capacity (t/h) |

Power (kW) |

|

MQZ1224 |

1.2X2.4 |

31 |

4.8 |

0-20 |

0.07-0.6 |

0.4-6.8 |

37 |

|

MQZ1245 |

1.2X4.5 |

31 |

5.2 |

0-20 |

0.07-0.6 |

1.6-12 |

45 |

|

MQZ1530 |

1.5X3.0 |

27.5 |

8.1 |

0-25 |

0.07-0.4 |

2.9-16.5 |

65 |

|

MQZ1557 |

1.5X5.7 |

29.2 |

15 |

0-25 |

0.07-0.4 |

4-25 |

95 |

|

MQZ1645 |

1.6X4.5 |

27.5 |

14 |

0-25 |

0.07-0.4 |

4-24 |

95 |

|

MQZ1836 |

1.8X3.6 |

23.9 |

11 |

0-25 |

0.07-0.4 |

8-40 |

132 |

|

MQZ1864 |

1.6X6.4 |

23.9 |

18.5 |

0-25 |

0.07-0.4 |

8-60 |

155 |

|

MQZ2130 |

2.1X3.0 |

23.8 |

19.8 |

0-25 |

0.07-0.4 |

6.5-36 |

155 |

|

MQZ2136 |

2.1X3.6 |

23.8 |

27 |

0-25 |

0.07-0.4 |

8-61 |

155 |

|

MQZ2265 |

2.2X6.5 |

21.6 |

28 |

0-25 |

0.07-0.4 |

8-35 |

210 |

|

MQZ2430 |

2.4X3.0 |

22 |

22.5 |

0-25 |

0.07-0.4 |

7-92 |

210 |

|

MQZ2436 |

2.4X3.6 |

22 |

28 |

0-25 |

0.07-0.4 |

7-95 |

210 |

|

MQZ2465 |

2.4X6.5 |

22 |

36 |

0-25 |

0.07-0.4 |

7-110 |

260 |

|

MQZ2736 |

2.7X3.6 |

21.9 |

39 |

0-25 |

0.07-0.4 |

13-140 |

310 |

|

MQZ2745 |

2.7X4.5 |

21.9 |

43 |

0-25 |

0.07-0.4 |

13-150 |

320 |

|

MQZ2836 |

2.8X3.6 |

20 |

42 |

0-25 |

0.07-0.4 |

15-140 |

310 |

|

MQZ3060 |

3.0X6.0 |

19 |

70 |

0-25 |

0.07-0.4 |

100-145 |

630 |

|

MQZ3245 |

3.2X4.5 |

18.6 |

65 |

0-25 |

0.07-0.4 |

100-145 |

630 |

|

MQZ3260 |

3.2X6.0 |

18.6 |

86 |

0-25 |

0.07-0.4 |

120-150 |

800 |

|

MQZ3645 |

3.6X4.5 |

17.8 |

90 |

0-25 |

0.07-0.4 |

120-220 |

1000 |

|

MQZ3660 |

3.6X6.0 |

17.8 |

120 |

0-25 |

0.07-0.4 |

50-230 |

1250 |

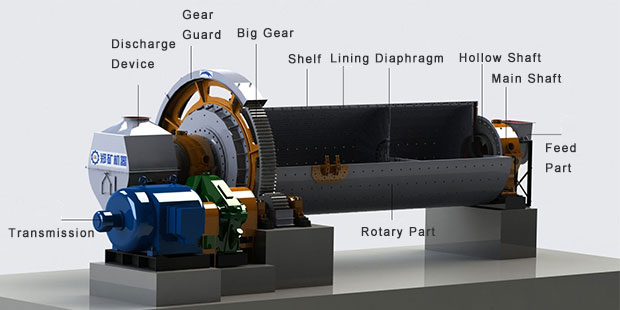

Ball Mill is made up of feeding part, discharging part, gyre part, transmission part, (decelerator, small transmission gear, generator, electrical control) and so on. The hollow axis adopts the cast steel and the lining can replace , the rotating big gear processes in the way of casting rolling gear. The barrel body is wearable well and bears wearable scale board. This machine runs steadily and works reliably.

Liner of ball mill is made of high-quality wear resistant material with high strength, wear resistance and long working life. The hollow axis adopts the cast steel and the lining can replace, the rotating big gear processes in the way of casting rolling gear. The barrel body is wearable well and bears wearable scaleboard. This machine run steadily and works reliably.

Please input your inquiry in below form. We will reply you as soon as possible!