Capacity: above 100,000 T/year

Application: Raw Material, Clinker Grinding Plant

Model: ZKRM

Outlet Size: 0-40 (mm)

1. ZK series raw vertical mill is developed with the features of high efficiency, energy-saving and environmental protection which is achieved after exchanging ideas with senior experts from home and abroad and making improvements based on same sector experience in the past years.

2. ZK technical center can help our client to finish feasibility study, environment impact assessment and safety assessment and also provides turnkey service with high efficiency.

3. ZK has its own various processing equipment and takes strict control measures on product quality, which results in fast delivery within a short time. Besides, ZK can guarantee completion and operation as scheduled with its strong service team for installation and after–sales service.

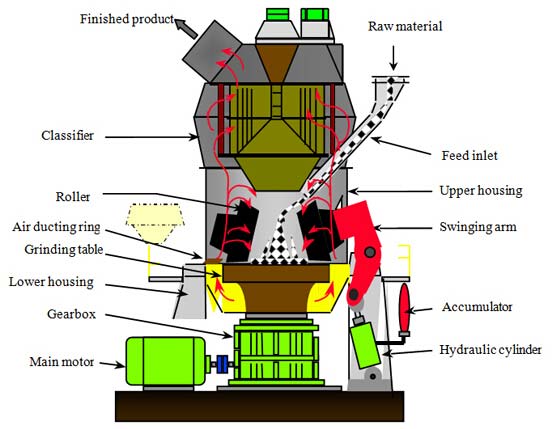

Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant. Vertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one. It can be widely used in cement, electric power, metallurgy, chemical industry, non-metallic ore, and other industries.

|

ZKRM Specification and technical parameter of raw meal vertical mill |

|

||||||

|

Model |

Capacity (t/h) |

Geometric diameter of grinding disc(mm) |

Grinding disc track diameter(mm) |

Raw material moisture(%) |

Raw meal fineness(%) |

Raw meal moisture(%) |

Main motor power(kW) |

|

ZKRM1300 |

20-25 |

1870 |

1300 |

<10% |

R0.08≤12% |

≤1% |

200 |

|

ZKRM1500 |

26-34 |

2180 |

1500 |

<10% |

R0.08≤12% |

≤1% |

280 |

|

ZKRM1700 |

40-50 |

2400 |

1700 |

<10% |

R0.08<12% |

≤1% |

400 |

|

ZKRM1900 |

60-70 |

2680 |

1900 |

<10% |

R0.08<12% |

≤1% |

500 |

|

ZKRM2200 |

85-110 |

2900 |

2200 |

<10% |

R0.08<14% |

≤1% |

800 |

|

ZKRM2400 |

95-130 |

3140 |

2400 |

<10% |

R0.08<14% |

≤1% |

900 |

|

ZKRM2800 |

120-160 |

3300 |

2800 |

<10% |

R0.08<14% |

≤1% |

1250 |

|

ZKRM3400 |

190-240 |

4560 |

3400 |

<10% |

R0.08<15% |

≤1% |

1800 |

Note: Grindability of raw materials(bond) Index ≤12kWh/t.

1. The combined classifier improves the powder selection efficiency.

2. It is not necessary to distribute material on the grinding plate before start-up. The roller can be lifted up and down automatically and start without load.

3. It is well sealed by welded arc plate and structure is simple and reliable.

4. With the help of roller turning device, it is easily to turn the roller out for maintenance.

5. Both sides of roller sleeve can be used so that the service life of refractory material is extended.

6. Grinding roller limit device can ensure a certain space between roller and plate, which avoids the direct friction and collision between roller and plate and enhances safety.

7. The grinding roller is driven by liquid -gas pressure. Pressure filling and adjustment and roller lifting can be remotely controlled without operator on-site.

8. The roller bearing is circularly lubricated by thin oil to enable it to work under low temperature and clean grease so that the service life is extended.

Please input your inquiry in below form. We will reply you as soon as possible!