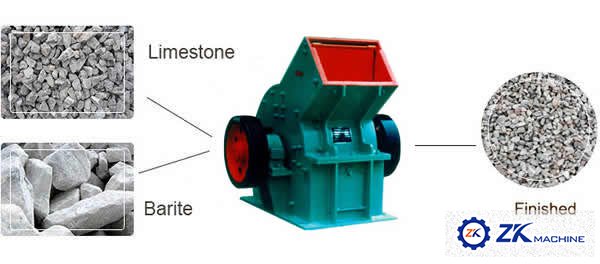

Model: PCH-0402 -- PCH-1221

Max Feed Size: 200-400 (mm)

Discharge Size: ≤30 (mm)

Application: stone, gravel, limestone crushing

1. It has large crushing ratio (normally is 10-25, or up to 50), high production capacity, even particles size, less over crushing phenomenon, simple structure, high weight and easy operation.

2. It can break material with size of 600-1800mm directly into size of 25mm or below.

|

Model |

Rotor model (mm) |

Max feed size(mm) |

Discharge size (mm) |

Motor model |

Power |

Capacity (t/h) |

|

PCH-0402 |

400x200 |

200 |

≤30 |

Y132M2-6 |

5.5 |

8-12 |

|

PCH-0404 |

400x400 |

200 |

≤30 |

Y160L-6 |

11 |

16-25 |

|

PCH-0604 |

600x400 |

200 |

≤30 |

Y180L-6 |

15 |

22-33 |

|

PCH-0606 |

600x600 |

200 |

≤30 |

Y225M-6 |

30 |

30-60 |

|

PCH-0808 |

800x800 |

200 |

≤30 |

Y280M-8 |

45 |

75-105 |

|

PCH-1010 |

1000x1000 |

300 |

≤30 |

Y315M2-8 |

90 110 |

160-200 |

|

Y315M3-8 |

200-245 |

|||||

|

PCH-1016 |

1000x1600 |

300 |

≤30 |

Y312-8 |

155 220 |

300-350 |

|

Y400-8 |

400-500 |

|||||

|

PCH-1216 |

1200x1600 |

400 |

≤30 |

Y400-8 |

280 355 |

500-620 |

|

Y450-8 |

620-800 |

|||||

|

PCH-1221 |

1200x2100 |

400 |

≤30 |

Y450-8 |

450 |

800-1000 |

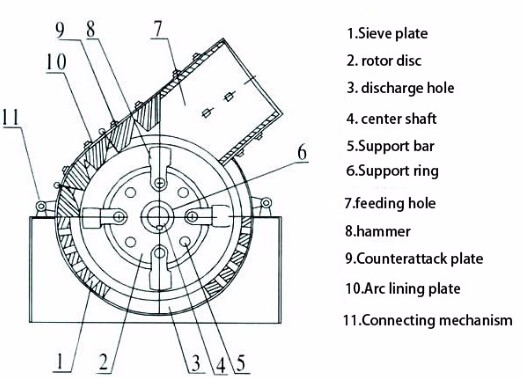

When material enters into the crusher, it can be crushed by the ring hammer which is revolved by the high-speed motor, at the same time material obtained the kinetic energy and rushed at the impact plate receiving the second crushing process, then falls on the screen sieve and be cut, extruded, and grinded by the ring hammer. At last the materials that come up to the standard can be discharged by the machine. Material can’t be crushed enters into the metal collector and should be eliminated regularly. Through replacement of sieve plate, discharge size of materials can be adjusted. Gap between rotor and sieve plate can be adjusted by the mechanism.

Please input your inquiry in below form. We will reply you as soon as possible!