Model: Ø1.0×10m - Ø3.6×36m

Capacity: 1-40 (t/h)

Power: 11-400 (kW)

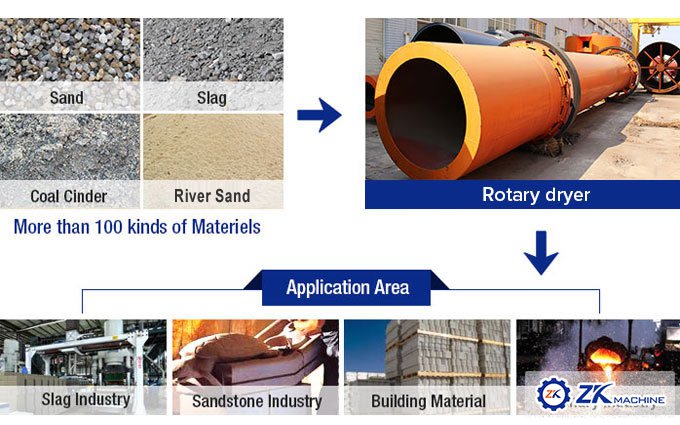

Application: mining ores, sand, clay, limestone, kaolin, cement, slag, coal, etc.

1. Shell adopts assembled structure, and its precision has been improved a lot, which will be convenient for transport.

2. According to different fuel properties, suitable raising plate will be used. This can make material receive more heat exchange.

3. Sealing is simple but efficient, which can improve capacity and the whole machine's performance.

4. Its matching combustion furnace is energy-saving type, which takes small area and is easy to adjust.

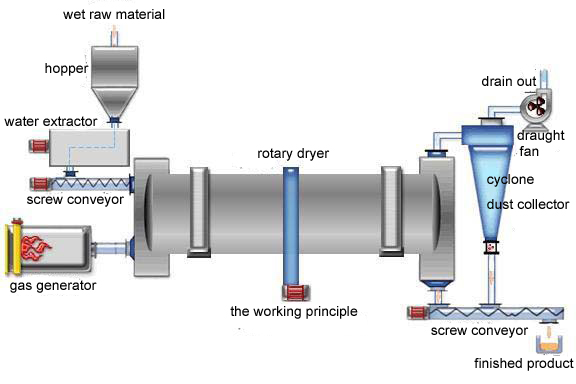

Rotary dryer is mainly used for drying various materials. The material inside the rotary dryer has heat exchange with the high-temperature flue gas through shell rotation and material lifting by the lifter. The rotary dryer has many good characteristics, like: high efficiency, big capacity, high running rate, saving energy, easy maintenance, and long working life. A variety of angles of the lifter will increase the heating exchange rate and shorten drying time. The feeding and discharging unit is installed with a thermocouple to control dryer temperature. The temperature change of the dryer's feeding end can be indicated by the thermometer to control the inner dryer temperature (generally 250-350°C)

Application of Rotary Dryer

1. The rotary drum dryer made in our factory is mainly used for chemical, mining, metallurgy industry, like mineral, slag, coal, metal powder, clay, kieselguhr, kaolin, sand, lignite, slica sand...

2. The rotary drum dryer can used for agriculture and fertilizer industry, like straw, stalk, leaves, starch pulp, dregs of decoction, pomace, bagasse, slurry, organic fertilizer, inorganic fertilizer and others.

3. It also can used for drying the special materials, such as all kinds of crystalline, argil, magnetic powder, inorganic mud, lime slurry, aluminum mud, mineral mud and others.

| Model (m) | Shell | Capacity (t/h) | Motor | Power (kW) | Reducer | |||

| Inner Diameter (mm) | Length (mm) | Slope (°) | Rev.Speed (rpm) | Motor Model | ||||

| Ø1.2X12 | 1200 | 12000 | 1.8 | 5 | 2-5 | YI60LM-6 | 11 | ZQ500 |

| Ø1.5X15 | 1500 | 15000 | 1.8 | 4.28 | 4-5 | YI60L-6 | 18.5 | ZQ650 |

| Ø1.8X18 | 1800 | 18000 | 1.8 | 5 | 6-8 | Y200LI-6 | 22 | ZQ650 |

| Ø2.0X20 | 2000 | 20000 | 2 | 3.38 | 7-10 | Y200L2-6 | 30 | ZQ650 |

| Ø2.2X22 | 2200 | 22000 | 1.8 | 2.8 | 9-14 | Y250M-6 | 45 | ZQ650 |

| Ø2.4X24 | 2400 | 24000 | 2.5 | 2.82 | 14-16 | Y280S-6 | 55 | ZQ750 |

| Ø2.8X28 | 2800 | 28000 | 2.5 | 2.55 | 20-22 | Y315S-6 | 90 | ZL115 |

| Ø3.0X30 | 3000 | 30000 | 2.5 | 2.69 | 22-24 | Y315LI-6 | 132 | ZL130 |

| Ø3.2X32 | 3200 | 32000 | 2.5 | 2.6 | 24-26 | Y315M-4 | 200 | ZSY450 |

| Ø3.6X36 | 3600 | 36000 | 2.5 | 2.51 | 30-40 | Y315L2-4 | 315 | ZL130 |

| Ø4.0X40 | 4000 | 40000 | 2.5 | 2.09 | 40-45 | YKK4003-4 | 400 | ZSY630 |

| Ø4.2X42 | 4200 | 42000 | 2.5 | 2.09 | 45-46 | YKK4005-4 | 400 | ZSY630 |

| Ø4.5X45 | 4500 | 45000 | 2.5 | 1.92 | 46-50 | YKK4502-4 | 500 | MH3S230 |

| Ø4.8X48 | 4800 | 48000 | 2.5 | 1.92 | 50-55 | YKK4504-4 | 630 | MH3S250 |

| Ø5.0X 50 | 5000 | 50000 | 2.5 | 1.92 | 55-60 | YKK4505-4 | 710 | MH3S260 |

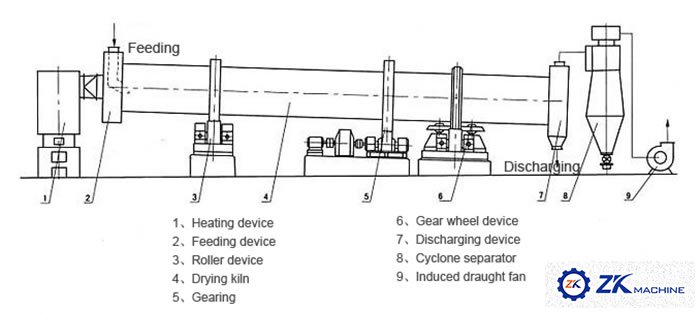

Rotary dryer is mainly compose of driving device, supporting roller, thrust roller, cylinder, kiln inlet, kiln outlet and sealing device.

1. 2-3 supporting points can guarantee the contacting surface between supporting roller and tyre is paralleled with axis line of cylinder during installation.

2. Supporting device is antifriction bearing (occasionally uses slide bearing). This design has simplified the supporting device of supporting roller, and reduced the useless power loss during operation. It has the features like easy operation and maintenance.

3. Suitable shim between tire and shell will ensure the tire ring on the shell tightly to increase the shell strength.

4. The main driving system uses new type AC variable frequency technology. Compared with electromagnetic speed control and DC speed control, that can save energy, have large range & high precision of speed regulation, high efficiency and running smoothly.

5. Radial direction contacting type sealing device is adopted at kiln inlet and outlet. They are perfect suitable for dimension tolerance of cylinder and skewing movement of cylinder. This sealing device’s feature is good performance, longer working life and easy for replacement.

Please input your inquiry in below form. We will reply you as soon as possible!