Cement is a key component of building materials. Its main raw materials include limestone, silicates, and aluminates. Cement grinding lines are a crucial step in cement production and are core equipment. This line features a simple structure and a high degree of automation.

Project Overview: This month, our 8-10 tph cement grinding equipment for Armenia was delivered to our factory. This project marks our third cement grinding line in Armenia. Our equipment quality, line design, and high-quality after-sales service have been highly recognized by our customers!

Project Location: Yerevan, Armenia

Project Name: 8-10 tph Cement Grinding Line

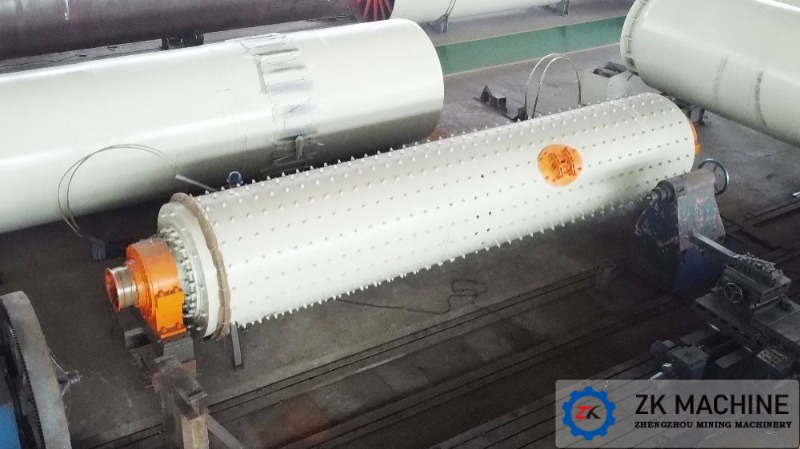

Main Equipment: Ø1.83 x 9 m ball mill, PPC32-3 bag filter, ZM64 bag filter, etc.

Conclusion:

Cement grinding is the final step in cement production and consumes the most electricity. Its primary function is to grind cement clinker (and other auxiliary materials such as slag and gypsum) into an appropriate particle size (measured by fineness, specific surface area, etc.), creating a defined particle size distribution, increasing the hydration surface area, accelerating the hydration rate, and meeting the setting and hardening requirements of the cement paste. Therefore, the selection of grinding equipment is particularly important.

Our cement production line equipment comprises a feeding system, grinding system, dust removal system, packaging system, and electrical and control systems. This line features a simple structure, high degree of automation, easy operation, and a low failure rate. We highly recommend it to our customers.