Processing capacity: 1000-20000 t/a

Raw material: Spodumene, lepidolite, lithium ore

Rotary kiln diameter: 1.5-4.5m.

1.The production line is stable and easy to operate.

2.The kiln adopts wireless temperature measurement and monitoring system to control working parameters more effectively and accurately.

3.Strengthen waste heat recovery, energy saving effect is good.

4.The new dust removal device has good dust removal effect and low construction cost.

With the rapid development of electronics, automobile, information and other industries, lithium, as the basic material for the production of secondary lithium salts and lithium metal products, has become the most important product in lithium compounds, and the market demand increases by 6% to 8% every year. In recent years, the application of lithium as cathode material of lithium ion battery, electrolyte, surface elastic wave element material is becoming mature, the added value of products is increasing, and the market demand is expanding rapidly. nd increases by 6% to 8% every year. In recent years, the application of lithium as cathode material of lithium ion battery, electrolyte, surface elastic wave element material is becoming mature, the added value of products is increasing, and the market demand is expanding rapidly.

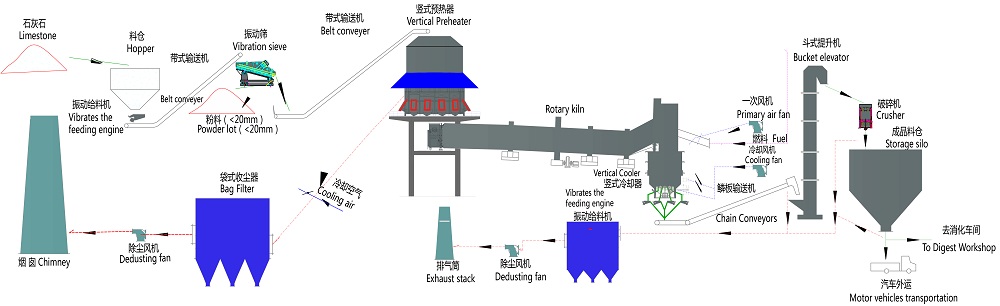

The production line for roasting and acidizing lithium ore with lepidolite, spodumene and other raw materials configured by our company has excellent product performance, stable production condition and easy operation, which has received positive recognition from users. The kiln adopts wireless temperature monitoring system and remote intelligent variable speed kiln condition control system, which is convenient for production personnel to adjust kiln condition in real time. The raw material crystal conversion rate is high, the acidification is complete, and the lithium leaching rate and lithium recovery rate are 15% higher than the traditional process. The energy consumption of production line can be reduced about 20% by using waste heat recovery from kiln tail for acidizing heat supplement.Cooling equipment adopts closed low temperature cycle technology, dust inlet is equipped with annular air seal device, the production workshop has a certain position in the field of dust reduction and environmental protection, effectively improve the operating environment.

Spodumene as Raw Material (Without Production of Other Products )

|

Final Products |

Annual Output(t/a) |

Spodumene Amount(t/h) |

Main Equipment Model |

||

|---|---|---|---|---|---|

|

Conversion Process |

Acidification Process |

Ball Mill |

|||

|

Lithium Carbonate LiCO3 |

5000 |

5-6 |

Roasting Kiln:φ2.8×50m; Cooler: φ2.6×40m |

Acidification Kiln:φ2.8×50m; Cooler: φ2.4×35m |

φ1.83×6.4m |

|

Lithium Carbonate LiCO3 |

10000 |

10-12 |

Roasting Kiln:φ3.5×60m; Cooler: φ2.4×40m |

Acidification Kiln:φ3.5×50m; Cooler: φ2.4×40m |

φ2.4×8m |

Domestic Standard Configuration List of 10,000 t/a Lithium Carbonate Production Line ( With Production of Other Products )

|

Final Products |

Annual Output(t/a) |

Spodumene Amount(t/h) |

Main Equipment Model |

||

|---|---|---|---|---|---|

|

Conversion Rotary Kiln |

Acidizing Rotary Kiln |

Ball Mill |

|||

|

Battery Grade Lithium Carbonate LiCO3 |

10000 |

23-25 (dry basis) |

Conversion kiln: φ4.3×68m, with three-stage preheater; Converted material cooler: φ3.8×40m (spray water) or grate cooler |

Acidification kiln: inner jacketed hot blast furnace φ3.5×50m; Acidified material cooler: φ3.5×50m (external water spray) |

φ3.2×13m ball mill or ZKRM19.3 vertical mill |

|

Industrial Grade Lithium Carbonate LiCO3 |

1764 |

||||

|

Anhydrous Lithium Hydroxide Li(OH)(Li(OH)>=56.5%) |

10000 |

||||

|

Anhydrous Sodium Sulfate(Li2O 0.1%) |

48550 |

||||

|

Leaching Residue(Li2O 0.3%) |

210000 |

||||

Lepidolite as Raw Material

|

Final Product |

Annual Output of Lithium Carbonate(t/a) |

Amount of Mixed Raw Materials (about 60% of Lepidolite) (t/h) |

Main Equipment Model |

||

|---|---|---|---|---|---|

|

Rotary Kiln |

Cooler |

Ball Mill |

|||

|

Lithium Carbonate LiCO3 |

3000 |

15-18 |

φ3.5×60m |

φ2.5×23m |

φ1.83×6.4m |

|

Lithium Carbonate LiCO3 |

5000 |

25-30 |

φ4.2×72m | φ3×45m | φ3.2×13m |

Please input your inquiry in below form. We will reply you as soon as possible!