Capacity: 6000-50000(t/a)

Materials: Dolomite, Ferrosilicon etc

Application: Magnesium Calciantion Plant

Main Equipment: Dolomite Rotary Kiln, Preheater, Conveyor, Screen, Bag Filter etc

1. Energy Saving: The refractory lining of the rotary kiln consists of the outer insulation made of light refractory brick and inner compound refractory bricks, which will reduce the heat emission on the shell surface of the rotary kiln. The pre-heater at the end of the rotary kiln will recycle the heat to preheat the material and save fuel by 40% and increase the output by 30%.

2. Low Consumption: The vertical cooler at the discharge end of rotary kiln recycles the heat of the calcined dolomite which is discharged from the rotary kiln, and will preheat the secondary air up to 600℃. The vertical cooler is integrated with kiln hood to prevent the waste caused by heat emission from the discharged calcined dolomite.

3. Envioronmental Protection: Two phases of dust collection including cyclone filter and bag filter, will control the dust emission below the limitation of the national standard.

4. High Degree of Automation: PLC control system improve the working efficiency.

Dolomite rotary kiln is designed according to dolomite calcination characters and Pidgeon process requirement. That is the key equipment in the calciantion process. The dolomite produced by rotary kiln with stable quality, high activity and low ignition loss that can make higher magnesium extraction rate and silicon utilization rate to save running cost. The rotary kiln is the most suitable equipment for produce magnesium. The new type energy-saving rotary kiln designed by ZK Corp. has own patent and formed dolomite calcination standard for magnesium industry in China.

We can provide plant design, equipment & spare parts fabrication, installation and technical support service for magnesium metal production plant & magnesium oxide production plant from dolomite/magnesite calcination, production capacity of single production line is 5,000-25,000 tons per year. We are leading manufacturer of complete equipment for magnesium production line, and over 90% market share. We have done many successful projects in both China and overseas countries. POSCO is world class iron and steel supplier in Korea. Their magnesium alloy production lines are supplied by us. We also have light burnning magnesite project with capacity 100TPD in Tanzania.

|

No. |

Item name |

Parameter for different production capacity |

|||

|

5000t/a |

10000t/a |

15000t/a |

20000t/a |

||

|

1 |

Vibration screen |

ZSGB1020 |

ZSGB1020 |

ZSGB1230 |

ZSGB1250 |

|

2 |

Inclined Belt Conveyor |

DJ.B500 |

DJ.B500 |

DJ.B650 |

DJ.B800 |

|

3 |

Vertical Preheater |

Quadrangle |

Hexagon |

Octagon |

Decagon |

|

4 |

Rotary kiln |

Φ2.5×40m |

Φ3.0×50m |

Φ3.3×55m |

Φ38×58m |

|

5 |

Vertical cooler |

3.6×3.6 |

3.6×3.6 |

3.6×3.6 |

4.1×4.1 |

|

6 |

Cyclone filter |

Ø2500 |

Ø2800 |

2×Ø2000 |

2×Ø2800 |

|

7 |

High temp. bag filter |

ZL2100 |

ZL2350 |

ZL3300 |

ZL4300 |

|

8 |

High temp. fan |

N=315kW |

N=355kW |

N=500kW |

N=800kW |

|

9 |

Bag filter |

ZM32-4 |

ZM32-5 |

ZM64-4 |

ZM64-6 |

|

10 |

Ball mill |

MQG1.83×7m |

MQG2.2×7m |

MQG2.4×7m |

MQG3.0×9m |

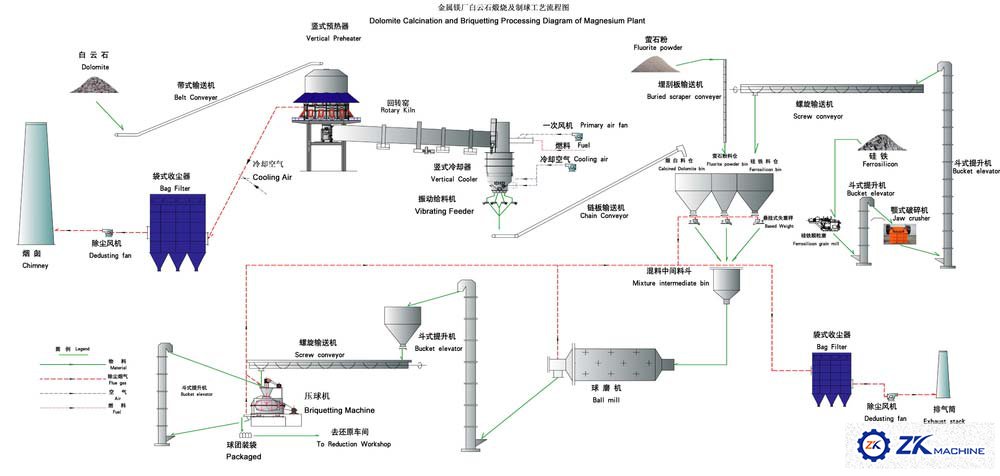

Dolomite Calcination Process Flow:

Step 1: Calcined - The calcined dolomite granular

a. Process introduction: As a result of mining dolomite is too large in volume, so crushing and calcining bulk dolomite, make its become particles.

b. Main equipments:Jaw Crusher,Conveyor,Vibrating screen,Vertical preheater,Rotary kiln,Vertical cooler,etc.

Step 2:Grinding and balling - Raw material production and storage

a. Process introduction: Calcined dolomite, using a ball mill and other equipment to the grinding ball material, storage after production well.

b. Main equipments:Electronic batching scale,Bucket elevator, Ball mill, Screw conveyer ,FU chain conveyor,etc.

Step 3:Reduction treatment - Reduction treatment raw materials

a. Process introduction: Refine the raw materials, product the qualified products and sales.

b. Main equipments:Reduction furnace,Wind machine Vacuum pump,Jet pump,etc.

Step 4:Refine - Produce products

a. Process introduction:Use of a series of equipment, refine the raw material, create quality products and sales them.

b. Main equipments:Refining furnace,Electronic moisture device,Pouring pump,Continuous casting machine,etc.

Please input your inquiry in below form. We will reply you as soon as possible!