Capacity: 10-100t/d

Application: various solid wastes, hazardous waste, medical waste, chemical, industrial wastes and so on.

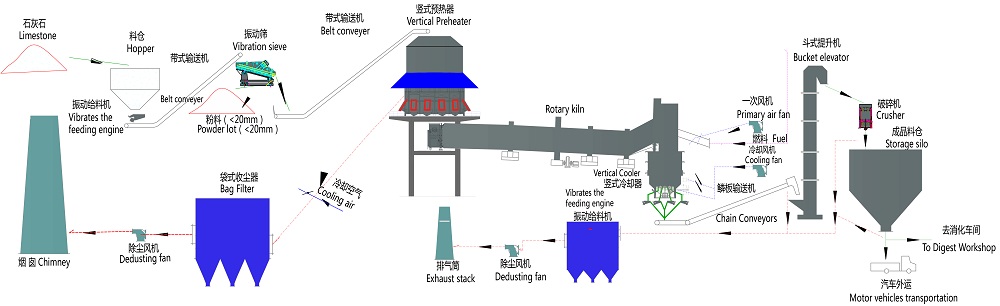

Main equipment: pretreatment and feeding system, rotary kiln + second combustion chamber combustion system, preheat recovery system, exhaust gas purification treatment system

1. It can treatthree kinds of wastes: waste water / waste gas / waste liquid at the same time;

2. The liquid wasteis fed by micron-level atomization, which burns completely and saves fuelconsumption;

3. Waste heat recoveryto generate benefits;

4. DCS control,high degree of automation.

Hazardous wastes refer to wastes with hazardous properties and characteristics, which have one or more of the hazardous properties such as toxic, explosive, flammable, corrosive, etc. The disposal of hazardous wastes at home and abroad is highly valued. Currently there are two main treatment methods on the disposal of hazardous wastes: incineration and landfill. Among them, the rotary kiln incineration technology is currently a widely used technology for the treatment of hazardous waste, and it is becoming an important approach for the harmless treatment of hazardous waste.

|

ec |

technical parametere |

motor |

supporting quantity |

|||

|

(m) |

rev |

slope |

output |

type |

power |

|

|

|

(r/min) |

(%) |

(t/h) |

(KW) |

||

|

1.6X32 |

0.58~2.85 |

4 |

2 |

YCT250-4A |

18.5 |

3 |

|

1.6/1.9X36 |

0.53~1.59 |

4 |

2.5~3 |

YCT250-4B |

22 |

3 |

|

1.9X39 |

0.53~1.59 |

4 |

3~3.4 |

YCT315-4A |

37 |

3 |

|

2.2X45 |

0.214~1.64 |

3.5 |

4~5 |

YCT315-4B |

45 |

3 |

|

Y112M-4 |

4 |

|||||

|

2.5X50 |

0.62~1.5 |

3.5 |

5~6 |

YCT355-4A |

55 |

3 |

|

Y160M-6 |

7.5 |

|||||

|

2.5X55 |

0.62~1.5 |

3.5 |

5~6 |

YCT355-4A |

55 |

3 |

|

Y160M-6 |

7.5 |

|||||

|

2.8X55 |

0.62~1.5 |

3.5 |

6~7 |

YCT355-4B |

75 |

3 |

|

Y160L-6 |

11 |

|||||

|

3.0X60 |

0.5~1.5 |

3.5 |

7~9 |

ZSN-280-11B |

125 |

4 |

|

Y160L-6 |

11 |

|||||

|

3.2X64 |

0.4~1.5 |

3.5 |

8~10 |

ZSN-280-11B |

190 |

4 |

|

Y180L-4 |

22 |

|||||

|

3.5X70 |

0.4~1.5 |

3.5 |

12~14 |

ZSN-315-082 |

280 |

4 |

|

Y180L-4 |

22 |

|||||

|

4X80 |

0.4~1.5 |

3.5 |

16~20 |

ZSN-315-12 |

355 |

4 |

|

Y200L-4 |

30 |

|||||

Process flow: pretreatment and feeding system---rotary kiln + second combustion chamber combustion system---waste heat recovery system---exhaust gas purification treatment system---flue gas emission incineration system: including hopper, rotary kiln, secondary Combustion chamber, and auxiliary equipment such as combustion and fan. Waste heat recovery system: including waste heat boiler and boiler auxiliary system equipment. Flue gas purification system: Cool the flue gas in the incinerator and remove harmful substances, and discharge it after meeting the emission requirements. Including quench tower, dust collector, scrubber, flue gas heater, activated carbon supply system, ash removal system, etc. Flue gas discharge system: including induced draft fan, chimney, etc.

Please input your inquiry in below form. We will reply you as soon as possible!