Model: Aluminum Ash Ball Mill

Discharge fineness: : 0.074-0.89mm

Capacity: 1.7-90 (t/h)

Application: Widely used in aluminum ash, metallurgy, chemical and other industries.

1. Improving the recovery rate: Compared with the existing recovery methods, aluminum ash ball mill (now using aluminum ash concentrator, aluminum ball mill, ore washing machine), the recovery rate will increase by at least 10%;

2. Less investment: The feed out of aluminum ash mill is installed with a cylinder with a tapping function. Compared with the traditional method, there is no need to use the linear vibrating screen, which can save the equipment cost and reduce the operating costs;

3. Energy saving: The operation of aluminum ash ball mill does not require oil, coal and other precious energy, which can utilize the heat from ash to process the aluminum ash and save a lot of energy;

4. Less dust: The aluminum ball mill is installed with dust cover, greatly reducing the dust;

5. Short processing time: Aluminum ash ball mill produced by our company can increase the processing ability of aluminum as for the production unit, which can handle 20-50 tons per day;

6. Significant economic benefits: High recovery rate per ton of aluminum ash, and then direct economic benefits even could reach to several thousand USD per ton;

7. Fully automatic system: Aluminum ash ball mill can save considerable labor costs for per production unit, greatly reducing the labor intensity of workers and reduce work-related accidents.

The aluminum ash ball mill is a special beneficiation mill developed by our company after years of improvement based on the characteristics of aluminum ash. This machine has high controllability in the production of aluminum ash, and combines a series of advantages such as energy-saving ball mills to achieve energy saving. Features such as high efficiency and low pollution.

The function of the aluminum ash ball mill is to grind the aluminum in the aluminum ash through steel balls to stretch the aluminum into flake and foil-like aluminum. This is a relatively important process step for extracting aluminum from the aluminum ash. Aluminum ash can be used as the raw material for the production of aluminum chloride series water purifiers, so that the waste aluminum can be recycled to the best use, or the treated aluminum ash can be used as a joint material to replace cryosine as the raw material for electrolytic aluminum.

|

Specification |

Output (t/h) |

Rev |

Grinding |

Power(kw) |

Reducer |

|

|

Model |

Ratio of speed |

|||||

|

Ф1.2x4.5 |

1.7 |

30.3 |

5 |

55 |

ZD30-8 |

4.481 |

|

Ф1.5x5.7 |

4.5 |

26.34 |

11 |

130 |

ZD40-7 |

4 |

|

Ф1.83x6.4 |

8.5 |

23.9 |

18 |

210 |

ZD60-8 |

4.5 |

|

Ф1.83x7 |

11 |

24.5 |

20 |

245 |

ZD60-8 |

4.5 |

|

Ф2.2x6.5 |

16 |

21.4 |

28 |

280 |

ZD70-9 |

5 |

|

Ф2.2x7.5 |

16-21 |

21.4 |

32 |

380 |

ZD70-9 |

5 |

|

Ф2.4x7 |

17-19 |

20.4 |

36 |

380 |

JDx560 |

6.33 |

|

Ф2.4x8 |

24-26 |

20.3 |

41 |

470/11 |

JD630 |

6.33 |

|

Ф2.4x12 |

35-38 |

20 |

62 |

800/11 |

JD800/ZD82.5-7-L |

6.33/99.96 |

|

Ф2.4x13 |

35-38 |

19.4 |

69 |

800 |

JDX800/MBY800 |

6.33 |

|

Ф2.6x13 |

50-55 |

19.5 |

83 |

1000 |

JDX800/MBY800 |

4.5 |

|

Ф2.8x5+3 |

36-478 |

18.6 |

56 |

500 |

ZDH80 |

4.5 |

|

Ф2.8x10 |

40-48 |

19.7 |

70 |

800 |

D110A |

37.5 |

|

Ф3x7+1.8 |

44 |

18 |

76 |

780/5 |

JD800/ZD82.5-8-L |

7.1 |

|

Ф3x9 |

28-32/50-55 |

18.34 |

78 |

1000/11 |

NZL1080/ZS110 |

8/280 |

|

Ф3x11 |

45-48 |

18.7 |

91 |

800 |

ZD100A-41 |

6.43 |

|

Ф3x12 |

55-58 |

18 |

100 |

1250 |

JS110-A |

41.1 |

|

Ф3.2x9 |

65 |

17.6 |

88 |

1250 |

JS110-A |

41.28 |

|

Ф3.2x10 |

55 |

17.6 |

98 |

1000 |

JS110 |

41.5 |

|

Ф3.5x10 |

73 |

16.8 |

118 |

1250 |

JS110-A |

? |

|

Ф3.6x7.5+2.5 |

90 |

17.3 |

125 |

1400 |

JDX900 |

7.1 |

|

Ф3.8x7.5 |

85 |

16.4 |

103 |

1400/22 |

NBY800/YNS620-90 |

5.6/90 |

|

Ф3.8x7.5 |

90 |

17 |

103 |

1600 |

JDX900 |

? |

|

Ф4.6x10+3.5 |

190 |

15 |

278 |

3550 |

JQS3500 |

? |

|

Ф4.6x10+3.5 |

210 |

15 |

278 |

3550 |

JQS3500 |

? |

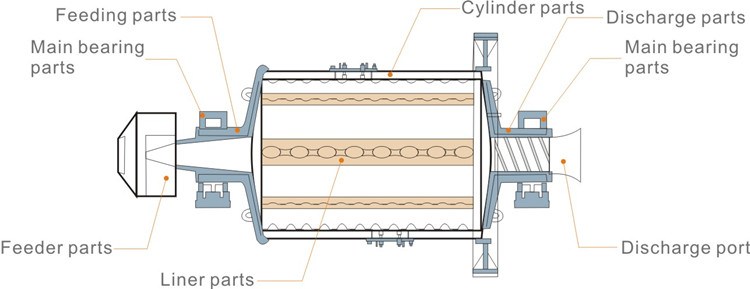

Aluminum ash ball mill is composed by feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance. The machine is with stable and reliable working condition.

Please input your inquiry in below form. We will reply you as soon as possible!