1. Project Introduction

Customer is a chemical factory in India, in demand of a granulator that can produce 2-3mm particles.

2. Project Description

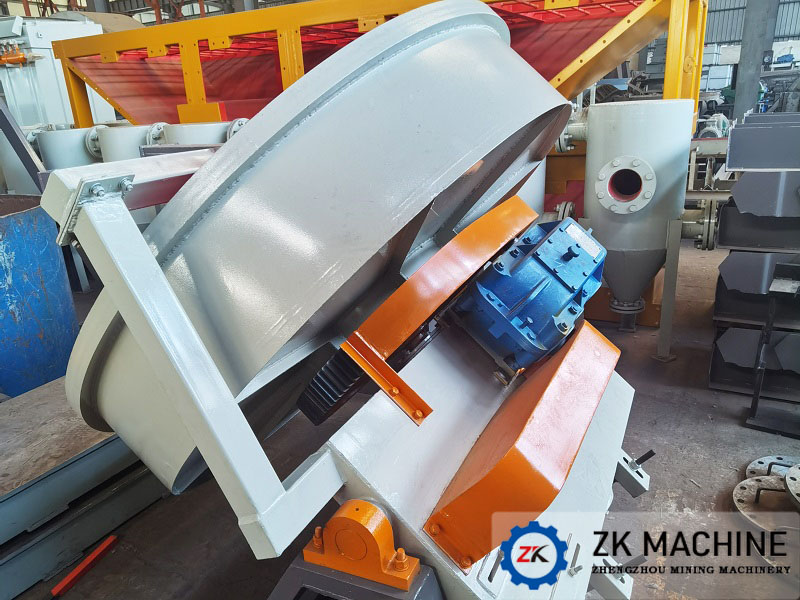

After communication with the customer, the customer's demand is clear: the raw material is metal oxide with a particle size of 13 microns. Objective To produce 2-3 mm particles. The customer first proposed the need for 500mm or 600mm diameter granulator. But it is not sure whether it is a plate granulator or a pot granulator. The yield should be more than 500 kg/hour. And continue to confirm to the customer whether the final particle strength requirements, whether the need to add adhesives, and bulk density. According to the customer's requirements and feedback, the technical staff selected PQ10 ball tray to meet the needs of customers. Explain to the customer why the pelletizer was chosen instead of the pot pelletizer. The ball forming plate is continuous discharging equipment, and the pot type granulator is intermittent discharging equipment. The discharging mode of the ball - forming plate and the discharging mode of the pot - type granulator are explained. And send a lot of pictures and videos to customers for reference. After technical discussion, the customer agreed to the selection of our technology.

Our technical personnel provide the general drawing and detailed technical parameters of PQ10 ball disc according to the above technical requirements. The customer is satisfied with the president and technical specifications.

3. Equipment Parameter

Model:PQ10

Diameter:1000mm

Raw materials: Metal Oxide

Final granule size:2-3mm

The equipment shall be completed within the specified time, equipped with well-known brand motors in China, and the trial video and pictures shall be taken and sent to customers for confirmation. The customer is satisfied with the quality of the equipment, we quickly spray paint, arrange shipping export packaging. And send the package picture to the customer. Arrange shipping date and delivery promptly.