1. Project Overview:

Project Location: China•Henan•Zhengzhou

Construction Unit: Henan Mingtai Technology Co., Ltd.

Product Name: Aluminum ash processing production line

Production Capacity: Recycle 50,000 tons of aluminum ash resources annually

Service scope: From raw material storage and transportation, preheating, drying, screening, to finished product storage and transportation system, environmental dust collection system, process design of electrical automation control system, plant planning, equipment supply, equipment installation and commissioning, after-sales training, etc.one-stop technical service.

2. Project Description

Henan Mingtai Aluminum Co., Ltd. (stock code 601677) is a limited company with aluminum deep processing as its main business. Ranked 29th in the 2019 Henan Top 100 Enterprises List.

Mingtai Aluminum is currently the only large-scale aluminum processing enterprise in my country that uses rotary kilns to recover aluminum slag. In order to further recover the residual salt slag after the aluminum slag is refined by the rotary furnace, the company optimizes and innovates on the basis of the international advanced salt slag recovery technology. The current annual recovery of 50,000 tons of salt residue project is about to be completed and put into operation. This project is a landmark project for my country's aluminum industry to enter ecological modernization. After the project is put into production, the company will realize a 100% green cycle from product to product.

3. Project Design Principles:

(1) On the premise of meeting the requirements of production scale, the host adopts stand-alone and single-line equipment to achieve the purpose of smooth and compact production line, save land, and increase land use rate.

(2) The auxiliary equipment is based on the principles of stability, reliability and energy saving to ensure normal production, high quality, high yield and low energy consumption.

(3) Fully integrate the local natural conditions, optimize the design plan under the process and production conditions, and reduce the project cost as much as possible.

(4) Conscientiously implement relevant national environmental protection, laws, regulations and standards, strictly control environmental pollution, reduce pollutant discharge, protect and improve the environment, and realize safe and civilized production.

4. Project Implementation

Henan Mingtai Technology Development Co., Ltd. plans to build an aluminum ash processing production line in Huiguo Town, Gongyi City, Henan Province, aiming to process aluminum ash and make solid waste resources. Henan Zhengzhou Mining Machinery Co., Ltd. will provide part of the production line's equipment and service.

5. Main Equipment

No. | Equipment Name | Model | Qty |

1 | Ball Mill | φ2.2×6.5m | 1Set |

2 | Double-layer Drum Screen | φ2.0×7.0m | 1Set |

3 | Rotary Dryer | φ2.2×18m | 1Set |

4 | Electric control | Matching | 1Set |

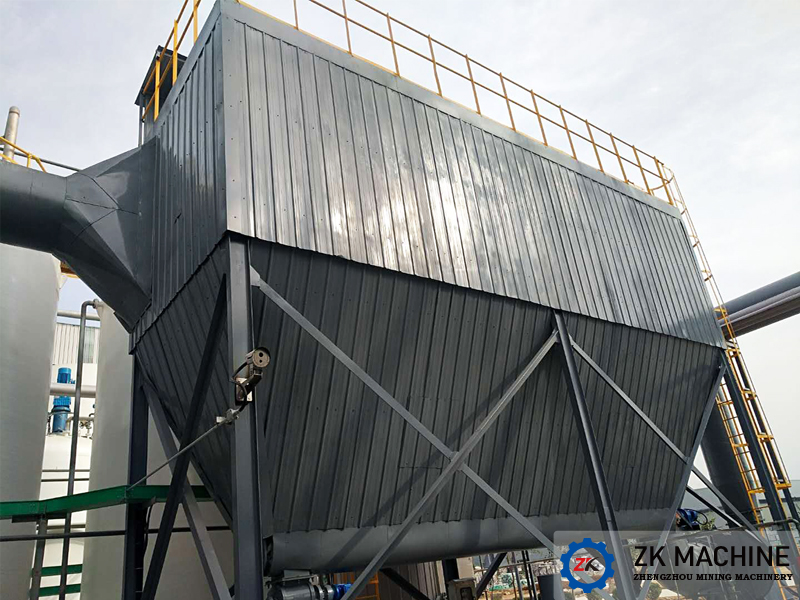

6. Project Photos

Please input your inquiry in below form. We will reply you as soon as possible!