Model : Dry Process Ball Mill

Applied Material: cement, iron ore, slag, etc.

Capacity: 0.65-165 (t/h)

Ball Loading: 1.5-338 (t)

1. Can be used for open-flow grinding, also applied to the circle-flow grinding equipped with separator.

2. Dry ball mill has the characteristics, such as wide adaptability to the material, continuous production, easy speed control, fineness grinding.

3. The moisture of feeding material cannot be high, otherwise it will appear the problem, such as bonding, poor discharge etc.

4. Dry ball mill outlet is straight, and also is equipped with an induced draft device.

Ball mill is mainly used for grinding in mining (metallic minerals and non-metallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, ect. It follows more crushing and less grinding principle to save energy. The feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

Applied materials: limestone, clinker, coal, granite, slag, quartz, feldspar, calcite, barite, zircon sand, fly ash, magnesite, molybdenite, hematite, fluorspar, zinc ore, spodumene, mica, aluminum powder, quartz sand, gold ore and other minerals etc.

We are a professional ball mill machine supplier in China, with rich project experiences from home and abroad, such as Iran, Kuwait, Turkey, Indonesia, Malaysia, Vietnam, India, Pakistan, Venezuela, Bolivia, Guyana, Russia, Armenia, Tanzania etc. If you have any inquiries about ball mill machine or ball mill spare parts, such as ball mill liner, grinding balls, large gear ring, cylinder, gears etc, please feel free to contact with us directly.

|

Model |

Revolving Speed |

Ball Loading |

Feeding Size |

Feedout Size |

Power |

Weight |

|

(r/min) |

(t) |

(mm) |

(mm) |

(kw) |

(t) |

|

|

Ф900×1800 |

36-38 |

1.5 |

≤20 |

0.075-0.89 |

18.5 |

5.85 |

|

Ф1200×2400 |

36 |

3 |

≤25 |

0.075-0.6 |

30 |

13.6 |

|

Ф1200×3000 |

36 |

3.5 |

≤25 |

0.074-0.4 |

37 |

14.3 |

|

Ф1500×3000 |

29.7 |

7.5 |

≤25 |

0.074-0.4 |

75 |

19.5 |

|

Ф1500×4500 |

27 |

11 |

≤25 |

0.074-0.4 |

110 |

22 |

|

Ф1830×3000 |

25.4 |

11 |

≤25 |

0.074-0.4 |

130 |

34.5 |

|

Ф1830×7000 |

24.1 |

23 |

≤25 |

0.074-0.4 |

245 |

43.8 |

|

Ф2100×3000 |

23.7 |

15 |

≤25 |

0.074-0.4 |

155 |

45 |

|

Ф2100×7000 |

23.7 |

26 |

≤25 |

0.074-0.4 |

280 |

59.5 |

|

Ф2200×4500 |

21.5 |

27 |

≤25 |

0.074-0.4 |

280 |

54.5 |

|

Ф2200×7500 |

21.7 |

35 |

≤25 |

0.074-0.4 |

380 |

64.8 |

|

Ф2400×3000 |

21 |

23 |

≤25 |

0.074-0.4 |

245 |

58 |

|

Ф2700×4000 |

20.7 |

40 |

≤25 |

0.074-0.4 |

380 |

95 |

|

Ф3200×4500 |

18 |

65 |

≤25 |

0.074-0.4 |

630 |

149 |

|

Ф3600×4500 |

17 |

90 |

≤25 |

0.074-0.4 |

850 |

169 |

|

Ф3600×8500 |

18 |

131 |

≤25 |

0.074-0.4 |

1800 |

260 |

|

Ф4000×5000 |

16.9 |

121 |

≤25 |

0.074-0.4 |

1500 |

230 |

|

Ф4000×6700 |

16.9 |

149 |

≤25 |

0.074-0.4 |

1800 |

249 |

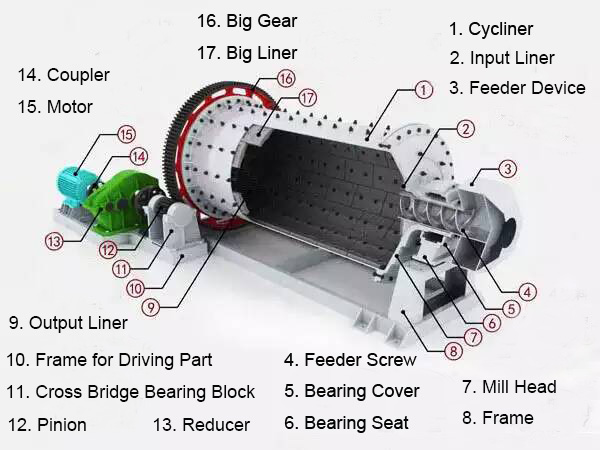

Ball Mill is made up of feeding part, discharging part, gyre part, transmission part, (decelerator, small transmission gear, generator, electrical control) and so on. The hollow axis adopts the cast steel and the lining can replace , the rotating big gear processes in the way of casting rolling gear. The barrel body is wearable well and bears wearable scale board. This machine runs steadily and works reliably.

Please input your inquiry in below form. We will reply you as soon as possible!