Operate Temperature (℃): ≤130

Thickness (mm): 1.8±10%-3.5±10%

Gram Weight(g/㎡): 500±5%-900±5%

Filter material: cotton fiber, wool fiber,and glass fiber

1. Normal filter material is 208 and 901 dacron, its operation temperature does not exceed 120℃, however, operation temperature of glass fiber bag is not more than 250℃.

2. Cotton fabric normally used for dusty gas without corrosivity and temperature below 80-90℃.

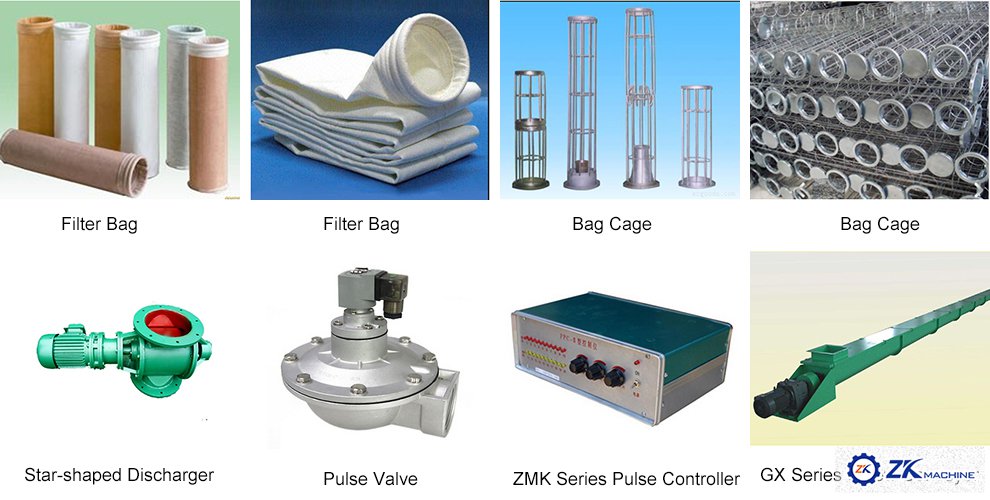

Filter bag is the key part for bag filter operation process, normally the cylinder shaped bags are vertically hanging inside of bag filter. For impulse bag filter, dust is attached to outside surface of bag, when the dusty gas go through bag filter, dust is collected and gathered on the outer surface of bag, and clean air goes through bag and exhaust open air. The bag cage is inside bag for supporting. It can preventing bag fall down. And it also can use to clean dust cake and re-distribution.

Filter bag material is be selected in accordance with gas temperature, humidity and chemical characteristics, comprehensively considering factors such as particle size, weight, shape, grindability and dust concentration, filtering rate, way of dust removal, emission concentration and bag-type dust remover working system, etc. Normally, pulse-blowing bag-type dust remover uses needle felt and compartment blowback bag-type dust remover or mechanical vibration bag-type dust remover uses woven cloth.

|

Name |

Material |

Gram Weight |

Thickness |

Property |

Breaking Strength |

Breaking Elongation(10%) |

Operate Temperature |

||

|

Warp |

Weft |

Warp |

Weft |

||||||

|

Polyester needle-felt filer bag |

Polyester/polyester filament fabric |

500±5% |

1.8±10% |

12 |

>1200 |

>1600 |

<30 |

<45 |

≤130 |

|

Polyester anti-static needle felt filter bag |

Polyester/polyester antistatic fabric |

500±5% |

1.8±10% |

12 |

>1000 |

>1600 |

<30 |

<45 |

≤130 |

|

Medium temperature needled felt filter bag |

Dacron, PPS/glass fiber woven fabric |

700±5% |

2.2±10% |

8-12 |

>1000 |

>1500 |

<10 |

<10 |

≤170 |

|

Polypropylene filber needled felt filter bag |

PP, PP Yarn |

500±5% |

2.1±10% |

12 |

>960 |

>1060 |

<35 |

<55 |

≤90 |

|

FMS filter bag |

Aramid fiber, glass fiber/glass fiber cloth |

800±5% |

2.4-3.0 |

8-15 |

>1800 |

>1800 |

<10 |

<10 |

≤260 |

|

Nomex needle-felt filter bag |

Nomex/ nomex fabric |

500±5% |

2.2±10% |

17 |

>800 |

>1200 |

<35 |

<55 |

≤200 |

|

PPS needle-felt filter bag |

PPS/PPS filament fabric |

500±5% |

1.8±10% |

15 |

>1200 |

>1300 |

<30 |

<30 |

≤190 |

|

P84 needle-felt filter bag |

P84/P84 fabric |

850±5% |

3.5±10% |

8-15 |

>1800 |

>1800 |

<10 |

<10 |

≤220 |

|

Glass fiber needle-felt filter bag |

Glass fiber |

900±5% |

2.0±10% |

8-15 |

>1800 |

>1800 |

<10 |

<10 |

≤300 |

Filter material use fiber, which has cotton fiber, wool fiber, synthetic fiber and glass fiber etc.

Please input your inquiry in below form. We will reply you as soon as possible!